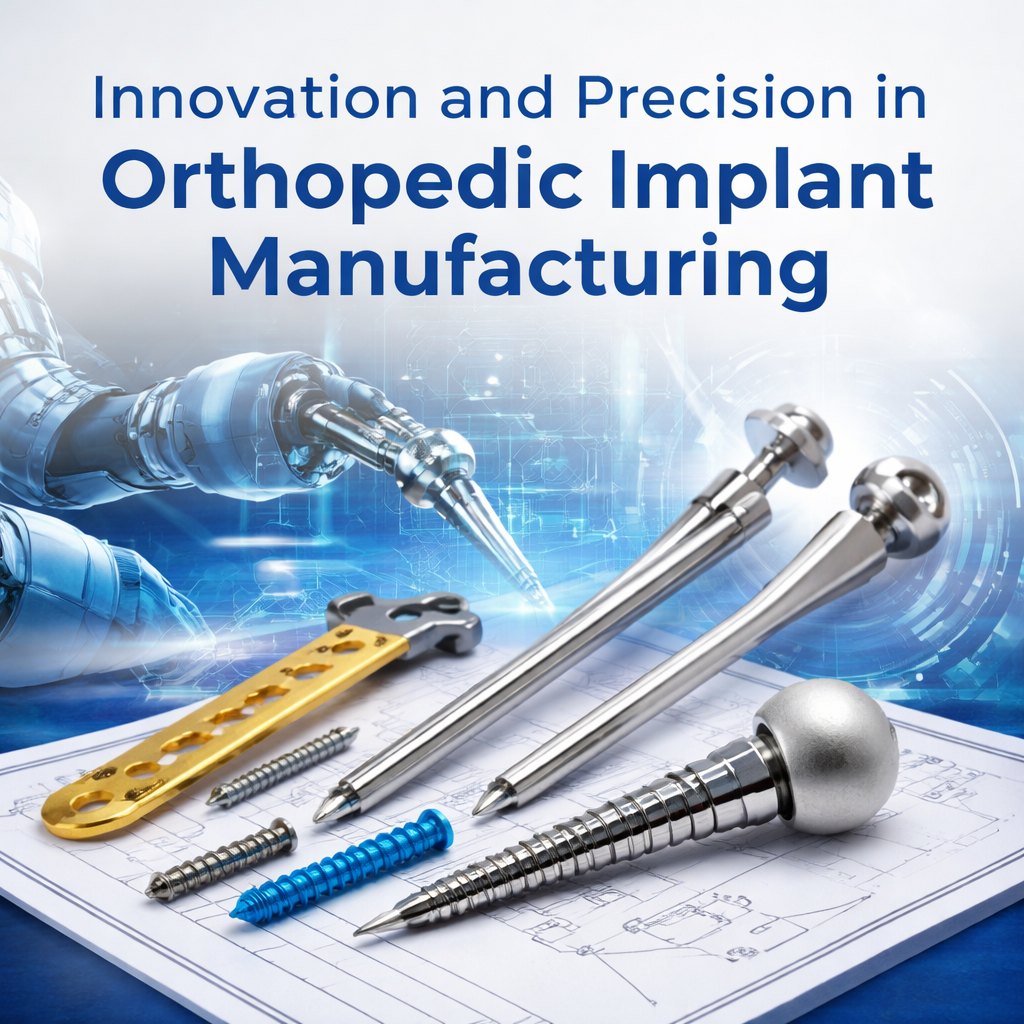

Guided by the vision and expertise of our mentor, Mr. Madhur Arora, we continuously focus on innovation, precision manufacturing, and customer satisfaction. His industry knowledge and strong leadership have helped us understand evolving market needs and achieve organizational excellence, making us a preferred choice among our valued customers.

750 +

Happy customer

reviews

FAQ

We hope you find what you are looking for. Explore faq`s.

Yes, we continuously work with surgeons to develop innovative and application-specific orthopedic solutions based on clinical requirements.

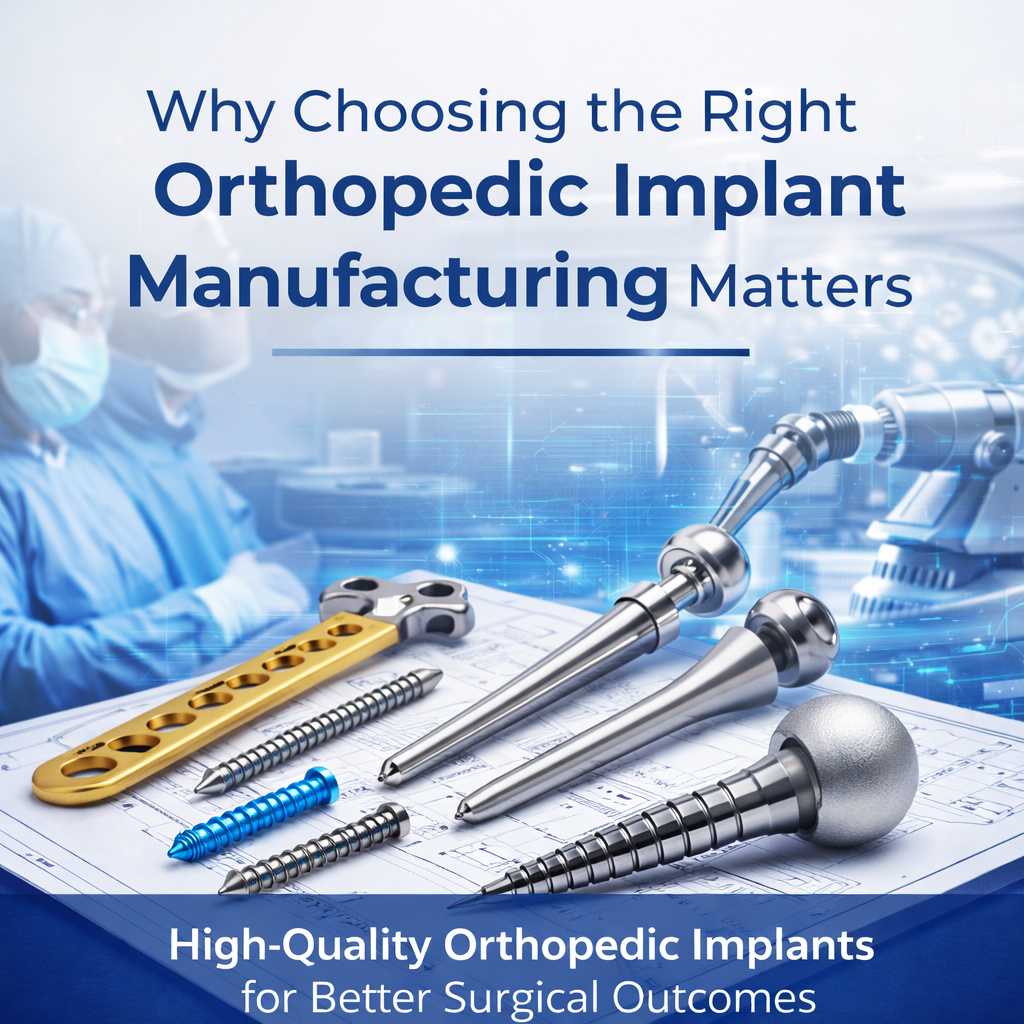

High-quality design, precise fit, and strong fixation help reduce complications, promote faster bone healing, and improve patient mobility after surgery.

Yes, we welcome partnerships with hospitals, distributors, and orthopedic suppliers both domestically and internationally.

Our manufacturing processes follow established quality systems, ensuring implants comply with recognized international orthopedic and medical device standards.

Yes, our implants are designed specifically for trauma fixation, fracture management, and joint reconstruction procedures, supporting reliable surgical outcomes.

Yes, all orthopedic implants undergo strict quality control checks including dimensional accuracy, surface finishing, and mechanical testing to meet international quality standards.

Our implants are manufactured using medical-grade titanium and stainless steel, ensuring high strength, corrosion resistance, and excellent biocompatibility.

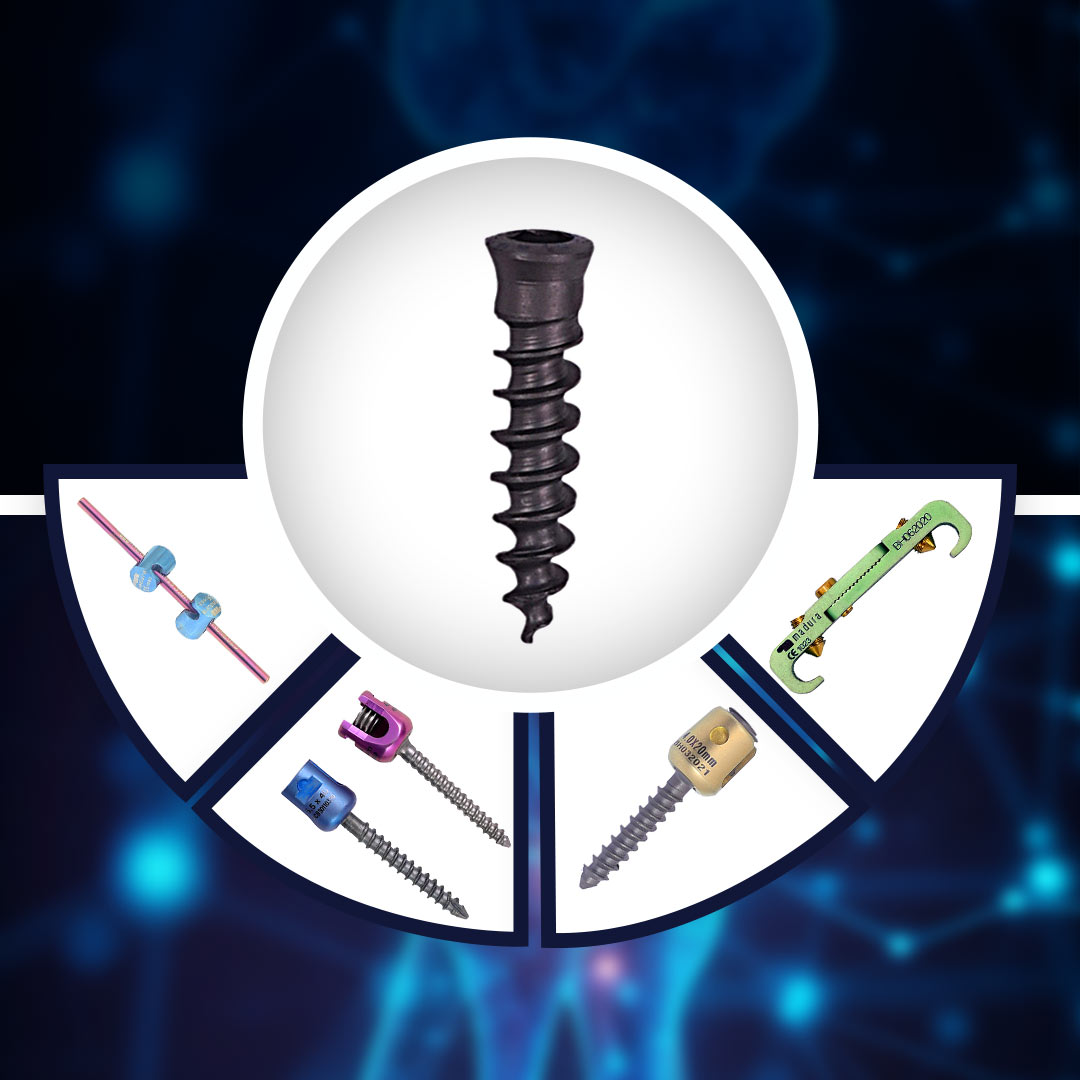

We manufacture a wide range of orthopedic implants including trauma plates, locking plates, cortical and cancellous screws, intramedullary nails, PFN/PFNA nails, bipolar prosthesis, and reconstruction plates.